What equipment still concerns insurers, loss adjusters, risk managers and operators?

Turbines, generators and transformers, between others. This is because of their cost, complexity, and exposure to potential large interruption periods when a loss occurs. This is particularly especial when damage is not that evident.

The photos below have caused interruption periods of many months (and years), yet the damage was not very clear from the outset.

What are the difficulties in assessing the extent of damage and reinstatement options of these equipment in Latin America?

Lack of OEM presence, elevated costs claimed from local suppliers, cost estimates not according to international standards, unavailability of components and long lead times, lack of local expertise, political risks, and many others.

Does it make sense for the same team of Forensic Engineers and Technical Experts to do the Root Cause Analysis (RCA) and Reinstatement Assessment?

Definitely, there are major links between an RCA and a reinstatement assessment, for example, the study of equipment behaviour in the months prior to a loss event and how this could have been gradually deteriorating over time, or it was reaching its end of life (i.e. RCA is wear and tear, and reinstatement either not payable or replacement is almost mandatory).

It is important to reduce the points of contact and requests for information at a critical level, as we know that RFI delays are quite common in Latin America.

In the same site inspection performed for the RCA, the Experts can gather enough evidence to begin the reinstatement assessment, thus saving time and costs.

What is crucial about Reinstatement Assessment in Power Plants?

We mentioned above the importance of turbines, generators and transformers. What we haven’t mentioned yet is how do we prepare a reinstatement plan.

This is our day to day, when assigned to review both the root cause and the reinstatement options for critical equipment we assess:

- The operational behaviour of the equipment in the year(s) prior to the loss event (i.e. the trends). This is done by a technical study of the operational data of the equipment, such as vibration, temperature, speed, and many others. This can be directly extracted from the SCADA system of the plant, or built from different monitoring devices (e.g. independent thermocouples, sensors, etc). We have written in a few occasions of the importance of IIoT (Industrial Internet of Things) and Big Data for predictive analytics, so operators can avoid catastrophic damages and insurers facing very large claims. (See C OVID-19 and Plant/Machinery Claims. Partial Solution => IIoT and The industrial internet of things (IIoT)

- The full maintenance and servicing background of the plant overall and the damaged equipment. We start by reviewing the OEM’s guidelines, and having a good understanding of the maintenance regimes of key components over time, which will help us to build a detailed timeline of how the plant has been maintained and when advice from service providers has or has not been followed by operators. We compare actual regimes with industry standards, in order to inform insurers the adherence or otherwise of these.

- We perform detailed inspections of all components in the affected equipment and similar “unaffected” models in order to compare and contrast, determine what is repairable and what is BER (beyond economical repair), and we perform NDTs (non-destructive testing) when possible. All this evidence is gathered in a forensic and careful manner, in order to utilise these facts if a case turns legal either by subrogation, or for separate disputes where we act as expert witnesses.

- We conduct detailed meetings with the operators in order to understand their views from the outset, their verbal comments on RCA and extent of damage, details on recommended local vendors, and also to understand the chances of other non-loss related works that could later be confused with the claim (the “opportunity” works).

- We catalogue all the affected equipment and components, and build a detailed table of damages, repair scenarios, costs, timings, and of course we provide our expert recommendations on the best reinstatement options.

- We monitor the works and liaise with all relevant vendors in order to guarantee that the works are performed on time and with the right quality, whilst closely monitoring any eventualities in order to propose solutions quickly and effectively, always in an economical manner.

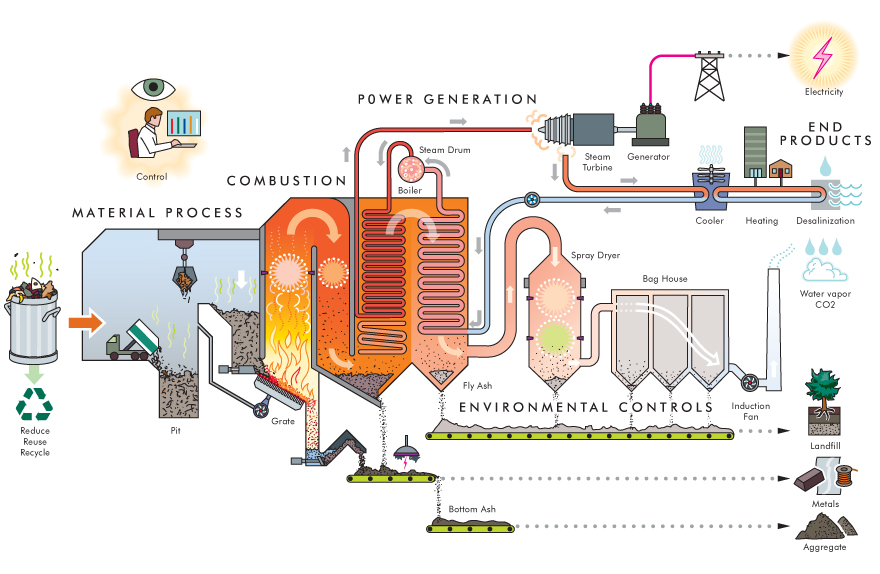

Do you know what are Waste to Energy Plants (Wte) and that these have a reduced life expectancy?

In general, we know that in classical power plants, turbines and generators can have a life expectancy of more than 50 years, if adequately maintained. However, waste to energy plants are different. Basically, the energy plant works by burning waste at high temperatures and using the heat to make steam which then drives a turbine, which later connects to a generator – directly or through a gearbox, and this generates electricity. The real life expectancy of key equipment in these plants is 20-25 years because of the aggressive environment these operate at. For example:

1. ABB, a world renowned manufacturer, specifically states:

“ A generator in a waste management plant has a normal life expectancy of 25 year ”. Moreover, ABB show in this article an example in a waste to energy plant in Denmark where the generator had only been running for 10 years, and their LEAP analysis showed a life expectancy left of 1-2 years (e.g. 12 years maximum).

2. A Public Department paper in the UK also shows the following:

“ Over the average 25 year planned lifetime of an energy from waste plant, the balance of the many factors that need to be considered to determine if it is the best solution may have changed. Once that planned lifetime has been reached it should not be automatically assumed that extending a plant lifetime beyond that originally envisaged will continue to deliver the same outcomes, although it may do. At this point all options including continued use and/or modification, through to closure and development of a new solution should be considered.”

DAC has also first-hand information from OEM’s themselves, that agree that 25 years is a realistic estimate (e.g. ELIN Motoren).

Although Waste to Energy plants are not that numerous in LATAM, studies show that there is a high trend for these to increase in the following years, especially when supported by Local Governments. According to the following article: “ Latin America’s waste-to-energy market is set to depict a growth in revenue…. Mexico, Brazil and countries in Rest of Latin America together constitute the Latin American market for waste-to-energy ”.

See Video on Wte plant in Mexico City:

With local presence in Mexico, Colombia, and Venezuela, as well as representatives in all of the Americas, Europe and Asia, DAC can perform both on site and desktop investigations to the required forensic detail, supporting the detailed task of loss adjusters and claim managers in determining the root cause of plant failure, as well as its reinstatement options.

About the autor:

Daniel A. Correa is the Managing Director of DAC Consulting , based in London, UK. Daniel is a Chartered Mechanical Engineer and Project Manager. He obtained his Mechanical Engineering degree from the Universidad Metropolitana in Venezuela, later completed a Master’s of Science in Engineering Project Management from the University of Manchester (UK), and is completing further studies from the University of Cambridge Judge Business School in the UK.

Daniel has acted as a Forensic Engineer and Expert Witness in dozens of cases worldwide, with a primary focus in EMEA, LATAM, and Asia.

Daniel is of the view that information sharing is of crucial importance for the insurance industry, especially for the investigation of large and complex matters. For this reason, his strategic position in London gives him a superb level of experience, which has allowed him to present in many forums worldwide, and aims at enriching the industry for its continuous growth over the years to come.

About DAC Consulting and Latin America

DAC’s experts are assigned as independent technical experts and forensic engineers for insurers, loss adjusters, brokers, and lawyers, when it comes to equipment failure, fires, contamination, and other perils. We assess the root cause of major and complex equipment losses, as well as the extent of damage, reinstatement options and timeline review for plants such as: refineries, power plants, offshore platforms, manufacturing plants, construction projects; and equipment such as: turbines, compressors, pumps, piping/pipelines, heat exchangers, vessels, tanks, generators, transformers, and many others.

With decades of experience in the Power and Oil & Gas Industry, DAC counts with over 50 experts worldwide , in specialist engineering fields such as: mechanical, electrical, instrumentation, piping/pipeline, process/chemical, civil/structural, materials, drilling, geothermal, SURF, HVAC, scheduling/delay analysis, cost estimation/quantum, commercial.

DAC Consulting looks at not only the technical elements of the reinstatement plans, but crucially at the schedules in order to mitigate any possible Business interruption (BI), as we know Business Interruption could be at least 3 times the cost of the Property/Physical Damage (PD). Similarly, we perform highly detailed delay analyses for DSU claims.

DAC Consulting has built over the years not only a good relationship with OEM’s and service providers, but also a good database on equipment costs, delivery times, installation costs, expert networks, and many others. This is crucial when estimating initial costs and interruption periods, and it is also crucial when discussing with local vendors and managing to reduce elevated initial estimates and “opportunity” works.

To serve the Latin American market we have a central hub in London, to connect the reinsurance markets with our local representatives, and experts in different countries, starting from the US, followed by Mexico , Colombia and Venezuela. Whilst we continue to expand our pool of experts in LATAM, we continue to train our personnel in order to improve our expert roles and cost efficiency in large and complex matters.

The post RCA and reinstatement assessment of major equipment in power plants appeared first on DAC Consulting.

Request a Consultation

Simply fill in the form below and one of our experienced team will contact you to discuss your requirement.

Alternatively give us a call today on +44 02071835624

or email us directly

Need Consultation ? No problem.

DAC Consulting Services is a professional consultancy founded in London by a group of senior engineers, project managers, former CEOs, and entrepreneurs with combined technical expertise.

FAQs

Got a question? We’re here to help.

-

DAC offers Engineering Advice?

Yes, DAC also gets involved in Project Development, Project Management, as well as Execution in order to support clients in the different life cycle of projects.

-

DAC works in the Middle East?

Certainly, around 30% of our cases are in the Middle East.

-

DAC counts with Delay and Quantum Experts?

Yes, apart from our technical experts, we count with multiple Delay and Quantum experts worldwide.

-

Have DAC Experts been cross examined in Court or ADR?

Most of them, and those who haven’t yet are being trained internally, and when possible through external organisations such as Bond Solon.

-

Can DAC offer lump sum budgets for investigation?

Yes, this has increasingly become a request from our clients, so we can help them in ascertaining the potential cost of our services.

-

Which office should I contact for any enquiry?

The fastest way to is to write to

London@dac-consultingservices.com, which consolidates all our enquiries worldwide.

News and Articles

DAC Consulting Services is a professional consultancy founded in London by a group of senior engineers, project managers, former CEOs, and entrepreneurs with combined technical expertise required to support international markets.

Useful Links

Useful Links

Get in Touch

All Rights Reserved | DAC Consulting Services